Industry Blog

The Benefits of Consolidating a Supply Base in Manufacturing

In the dynamic world of manufacturing, efficiency and reliability are the cornerstones of success. One strategy that has gained increasing recognition in recent years is the consolidation of a supply base. By reducing the number of suppliers and fostering strong partnerships with a select few, manufacturers can unlock a multitude of benefits. At Cass Precision … Read more

Cass Precision Machining’s Value-Added Services Elevate Customer Partnerships

In manufacturing, where innovation is paramount, and quality is non-negotiable, Cass Precision Machining is proud of its ability to provide a true partnership with our customers. As a partner you can depend on, Cass provides a collaborative force that amplifies success through our value-added services, nurturing a relationship that transcends conventional supplier-client dynamics. Partnering for … Read more

The Merits of Onshore Manufacturing: A Win-Win Strategy for Cass Precision Machining

In recent years, the manufacturing landscape has witnessed a remarkable shift, with an increasing number of companies recognizing the benefits of onshore manufacturing. This strategic decision to bring production back to the United States has proven advantageous for both businesses and the local economy. Cass Precision Machining, a renowned leader in U.S.-based precision machining solutions, … Read more

Cass Doubles Down on Manufacturing Infrastructure

As we move forward through 2023 Cass is embarking on an exciting time in our history. From our asset acquisition of TCR in 2020 and the purchase of the Micro-Fab division in 2021, Cass is positioned in 2023 to make even bigger investments in our people, our facilities, and our equipment for the benefit of our customers. … Read more

Importance of Supplier Managed Inventory

As the business world continues to recalibrate itself in a myriad of ways due to the global pandemic, one factor that became obviously clear in the manufacturing sector is the importance of supplier managed inventory. Supply chain issues arose like never before and forced organizations to assess and improve the resilience of their supply chains … Read more

The Advantages of Using Screw Machines

At Cass Precision Machining we give quite a few tours of our plant to both customers and prospective customers. These tours are something Cass enjoys doing and it’s always fun to see the “WOW” factor when visitors see just how impressive and effective screw machines can be. Cass believes that offering tours of our six … Read more

Manufacturing Adjusting to Post COVID Reality

While no one in manufacturing would say that workflows have “returned to normal” in the post-COVID world, many agree that a “new normal” has taken hold heading toward the end of 2022. At Cass Precision Machining we’ve settled into our new normal as far as our workflow and our customers go. Several changes have emerged … Read more

Avoid Downtime on Your Production Line with Quality Parts

The hallmark of any machine shop is the quality of the parts they produce. While quality is supposed to be a given, the pandemic led to plant shutdowns and slowdowns, including difficulties for manufacturing shops to attract new employees even with competitive pay and benefits. COVID-19 brought on other challenges, including workforce vaccination, travel restrictions, … Read more

4 Ways to Mitigate the Labor Shortage in Manufacturing

The manufacturing industry continues to suffer from an acute labor shortage. By the end of 2021, employment across the industry was down by nearly 400,000 personnel from pre-pandemic levels. Beyond causing stress, the lack of skilled workers has heightened workplace injury, product liability, and property damage risk for these businesses. And the pandemic isn’t the … Read more

Manufacturing Looks Brighter in 2022, But Challenges Persist

Manufacturing Looks Brighter in 2022 But Challenges Persist. Volatile market conditions have created significant challenges for the manufacturing industry since the pandemic began. Manufacturers have been forced to reexamine nearly every step of their process and look for ways to improve efficiency with their data, resources, and workforce. The last two years brought some unique … Read more

Cass announces James Larson as new President

Cass Precision Machining is Proud to Announce James Larson as Its New President! Cass is proud to announce that it has named James Larson as its new President. James is an experienced business leader who has been optimizing the customer experience, driving operational excellence, and developing new products for more than 30 years. Larson’s work history … Read more

Supply Crunch Continues to Push Prices Suppliers are Charging Businesses

As we wrote last year, the global supply chain crunch will continue to impact pricing, lead times and deliverables well into 2022 and beyond. Prices paid to U.S. producers posted a record annual increase of almost 10% in November, a surge that will sustain a pipeline of inflationary pressures well into 2022. The producer price … Read more

Cass Can Produce Parts for Exercise Equipment

The Cass Precision Machining website contains a page entitled “Industries Served.” On the page, we talk about our continued investment in new technology that leads to the best products at the greatest value. Our history dates all the way back to 1945, and over the years, we’ve worked hard to build a reputation as a … Read more

Assessing Supply Chain Shortages in 2022

China’s Battle with Decarbonization Poses Business Risks In Assessing Supply Chain Shortages in 2022, Climate Change is a major factor in the equation. In August UN Secretary-General Antonio Guterres called the report released by the UN’s Panel on Climate Change, “A code red for humanity.” The report says that humans are unequivocally warming the planet … Read more

Cass Precision Machining Acquires Micro-Fab

Cass Precision Machining announced that it acquired Micro-Fab, a precision machining company based in Brooklyn Park, MN, on July 1, 2021. Micro-Fab will operate as a division of Cass Precision Machining, serving the aerospace, defense, and medical industries.

How to Find Manufacturing Success During the Post-Covid Supply Crunch

As the global economy slowly recovers from the impact of the COVID-19 pandemic, the worldwide supply crunch is intensifying, spreading from one country to another and from one industry to another. Breaking Down the Supply Crunch When the pandemic spread in the spring of 2020, there was a lot of panic buying by consumers who … Read more

Industrial Rapid Prototyping With CNCs

Companies need to develop and introduce new products faster to remain competitive in this fast-moving modern-day consumer market. Since faster product development and technology innovation are key to a company’s success, rapid prototyping becomes the most important element of new product development. Industrial rapid prototyping bridges the gap between concept design and manufacturing for production. … Read more

Cass Has Machining Job Openings–Operators and Machinists Wanted

Are you feeling underappreciated and under-stimulated at your current job? Were your hours cut, or did you lose pay because of the pandemic? If so, we have good news for you, as Cass Precision Machining has machining job openings, with both operators and machinists wanted. Cass can be the great change in careers you’re looking … Read more

Understanding Industrial Manufacturing | Cass Precision Machining

The industrial manufacturing industry is responsible for the fabrication of products intended for industrial use from raw materials. When asking the question, “what is industrial manufacturing?” one has to look at the output itself (the products produced) which ranges from large machinery like bulldozers and cranes to smaller products such as wheelchairs and circuit boards. … Read more

Cass Delivering Prototype Machined Parts

In 2020 Cass Precision Machining launched C-RPM (Cass Rapid Proto Machining), a new service that supports Cass customers with build-to-print rapid prototyping parts. The response from customers has been exceptional and Cass has now produced over 30 prototype parts. The goal of C-RPM is to supply customers with machining expertise and design for manufacturing engineering consulting … Read more

Cass Does its “Part” for the Commemorative Air Force

Sometimes a job is about far more than the bottom line. Cass Precision Machining was honored to recently volunteer their time, material, and machines to produce a part for the Commemorative Air Force Airbase, located in Mesa, Arizona. The Commemorative Air Force are flight museums dedicated to the education and enjoyment of present and future … Read more

Cass is More Than Quality Machined Parts

When Cass Precision Machining rebranded itself just over three years ago, we added a pretty simple tagline that speaks volumes: Consistent. Reliable. Trusted. Those are three personality traits that we all look for in the most important people in our lives—our parents, teachers, coaches, significant others, and our closest friends. What it comes down to … Read more

Announcing Single-Spindle Screw Machining Availability at Cass

At Cass Precision Machining we hope the end of the year finds you and your business safe and healthy. We are encouraged to see that, according to Deloitte Insights, the global manufacturing sector performed exceptionally well in November. The global manufacturing PMI (purchasing managers’ indices) increased to 53.7, a 33-month high and one of the … Read more

Reshoring Manufacturing Will Trend in 2021 and Beyond

That collective sigh of relief you hear is that 2020 is winding down. Let’s be honest, some words nobody ever wants to hear again include pandemic, unprecedented, protocols, and coronavirus. 2020 was a rough year for a lot of different reasons, but as always, a new year brings with it a renewed optimism and new … Read more

Top 5 Questions to Ask When Considering Prototype Machining

Cass Precision Machining is proud to unveil Cass Rapid Prototype Machining (C-RPM), a new independent business unit operating within our five-building campus. C-RPM significantly ramps up our ability to serve you with prototype build-to-print contract machined parts services with accelerated delivery responsiveness. Operating as a business within a business, C-RPM’s “high touch” service connects you … Read more

Cass Hires Director of New Business Development

Cass Precision Machining is excited to announce that Derick White has joined Cass as the Director of New Business Development. Derick has a successful background in marketing and sales, along with developing strong sales organizations. “Derick and I have known each other for over eight years and have combined efforts in the past to strengthen … Read more

Cass’s 1st Annual Thanksgiving Food Drive

We had a blast teaming up to support the North-Suburban Emergency Assistance Response (NEAR) organization in Brooklyn Center, MN with our 1st annual food drive. Cass invited associates to bring in non-perishable food items or monetary contributions to donate to NEAR. We collected the items and added the monetary donations into the mix ($1=1 pound … Read more

Cass Precision Machining Celebrates Another Great Year With Its Hard-Working Team

For many of us, a large portion of our days are spent at work; in fact, the average person will spend 90,000 hours at work over a lifetime. So, it’s probably safe to say your job can make a huge impact on your quality of life. What’s more, without our employees, we don’t have a … Read more

How a Just-In-Time (JIT) Inventory Management Strategy Can Help Reduce Costs

In today’s manufacturing environment it is harder than ever to maintain your competitive position, and keep the right parts in stock that support your production floor. Partnering with your suppliers to manage your inventory and forecast your future requirements are the cornerstones of Just-In-Time (JIT) production planning and inventory management. If JIT is not integral … Read more

Part 2: Should You Change Your Machine Supplier?

Change can be good for a company – be it small tweaks in the way you do things or big operational shifts. As we said in Part 1 of this blog series, taking an honest look at what’s working for your business and identifying opportunities for improvement is always a good idea. As you approach … Read more

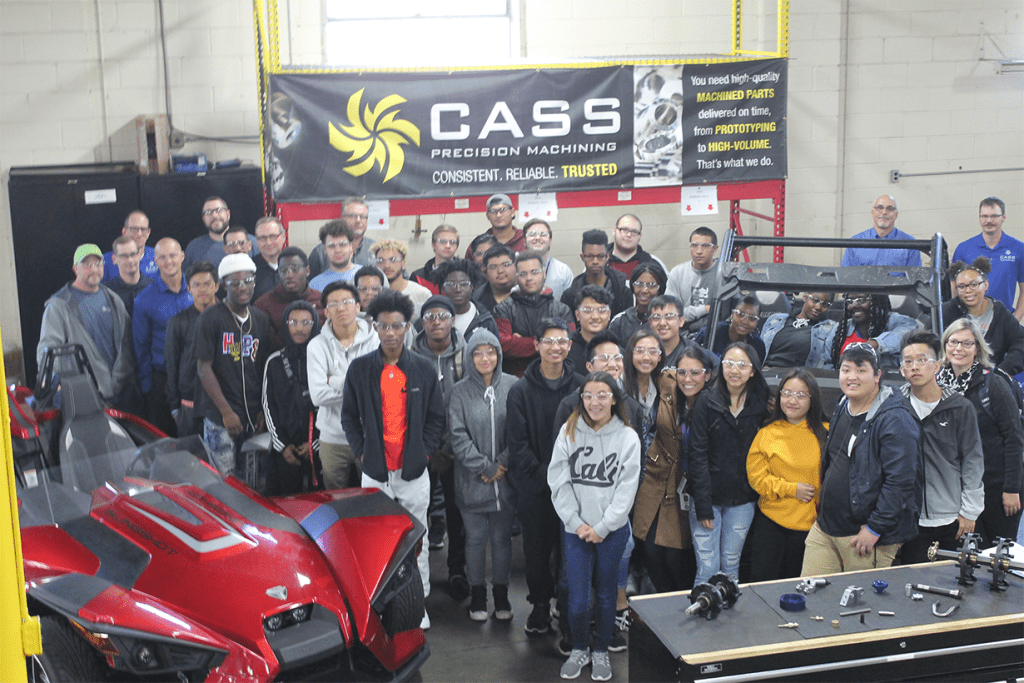

Cass Retools “Dream It. Do It. Minnesota Tours of Manufacturing” for Local High School Students

It was a real pleasure to welcome students back to Cass Precision Machining on Thursday, October 4th. Last year’s participation in Minnesota’s Dream it. Do it. Minnesota Tour of Manufacturing Day was so successful that we decided to reach out, in coordination with our sister company, Ajax Metal Forming Solutions, to a few of our … Read more

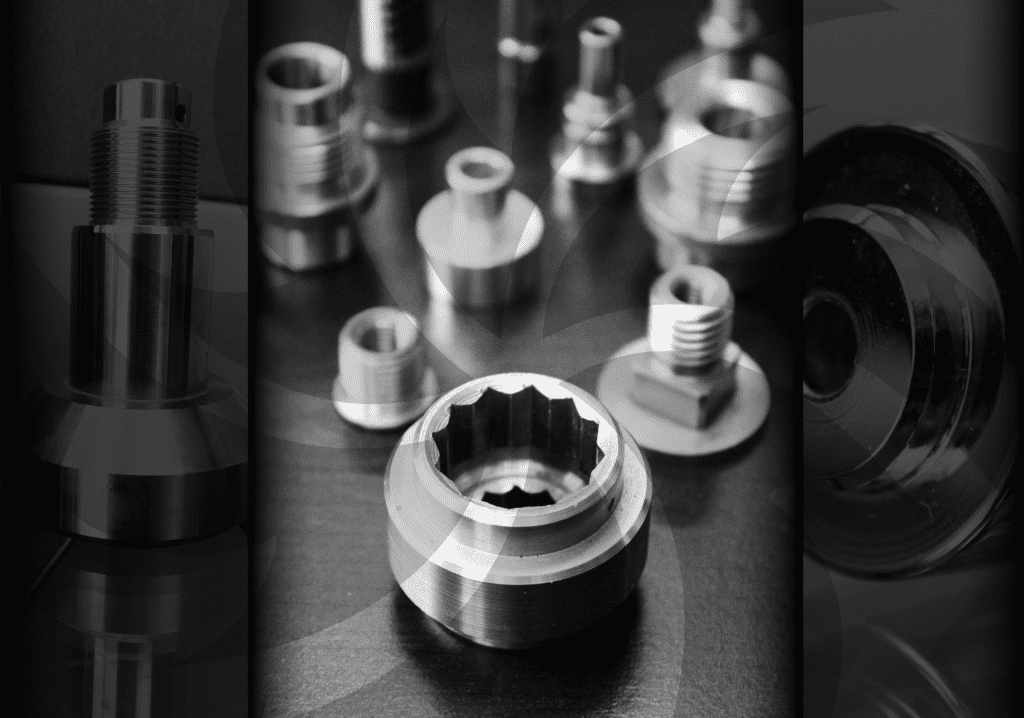

5 Questions to Ask Your High-Volume Machined Parts Supplier

What is High-Volume Production? The term “high-volume production” can mean many things to many people, from both a supplier and a customer perspective. What does “high-volume production” mean to us here at Cass? We’ve prepared an overview (View PDF) that illustrates the types of parts we run on a daily basis. Our hope is that … Read more

How the Quality Management System (QMS) Works at Cass Precision Machining

At Cass Precision Machining we’ve been humbled and honored to receive our share of recognition and awards over the years. The recognition is always nice, and it makes us proud of our company and our team—but it’s the knowledge that our customers are happy and satisfied with the work we do that gives us the … Read more

Steve Brown Retires After 51 Years with Cass!

We recently celebrated Steve Brown’s 51-year tenure at Cass Precision Machining! Cass President Jim Garvin is seen here shaking hands with Steve (the guy with the big smile on the right) following a special presentation that Jim delivered at our year-end meeting on December 18th 2017. Steve started at Cass Precision Machining as an inspector … Read more

Part 1: Should You Change Your Machining Supplier in 2018?

Another holiday season is upon us, which, of course, brings us near the end of another calendar year. While 2017 can only be described as “tumultuous” from a news headlines perspective, we hope the past year has been productive and successful for your business. It was a big year for us here at Cass Precision … Read more

Cass Participates in Dream It. Do It. Minnesota Tour of Manufacturing Day

Thursday, October 5th was a fun day for us at Cass Precision Machining. Our participation in Minnesota’s Dream it. Do it. Minnesota Tour of Manufacturing Day resulted in Cass hosting about 100 10th through 12th grade students and 10 faculty members from local schools. After welcoming students to the Cass campus, Cass President, Jim Garvin gave opening … Read more

Cass Screw Machine Products Rebrands as Cass Precision Machining

Hello and welcome to Cass Precision Machining’s new website! After completing an extensive research study that gave us outstanding feedback on our name, brand, and all the ways that we can best support your machining needs, we are proud to announce that we have rebranded the company as Cass Precision Machining.

Cass Precision Machining – Rebranding of Cass FAQ’s

As we cut over to our new name, we hope the completed FAQ’s below will address most of your concerns and questions regarding doing business with Cass. In the event you do not see the answer(s) you are looking for below, please feel free to address your question(s) to us via posting a message in … Read more