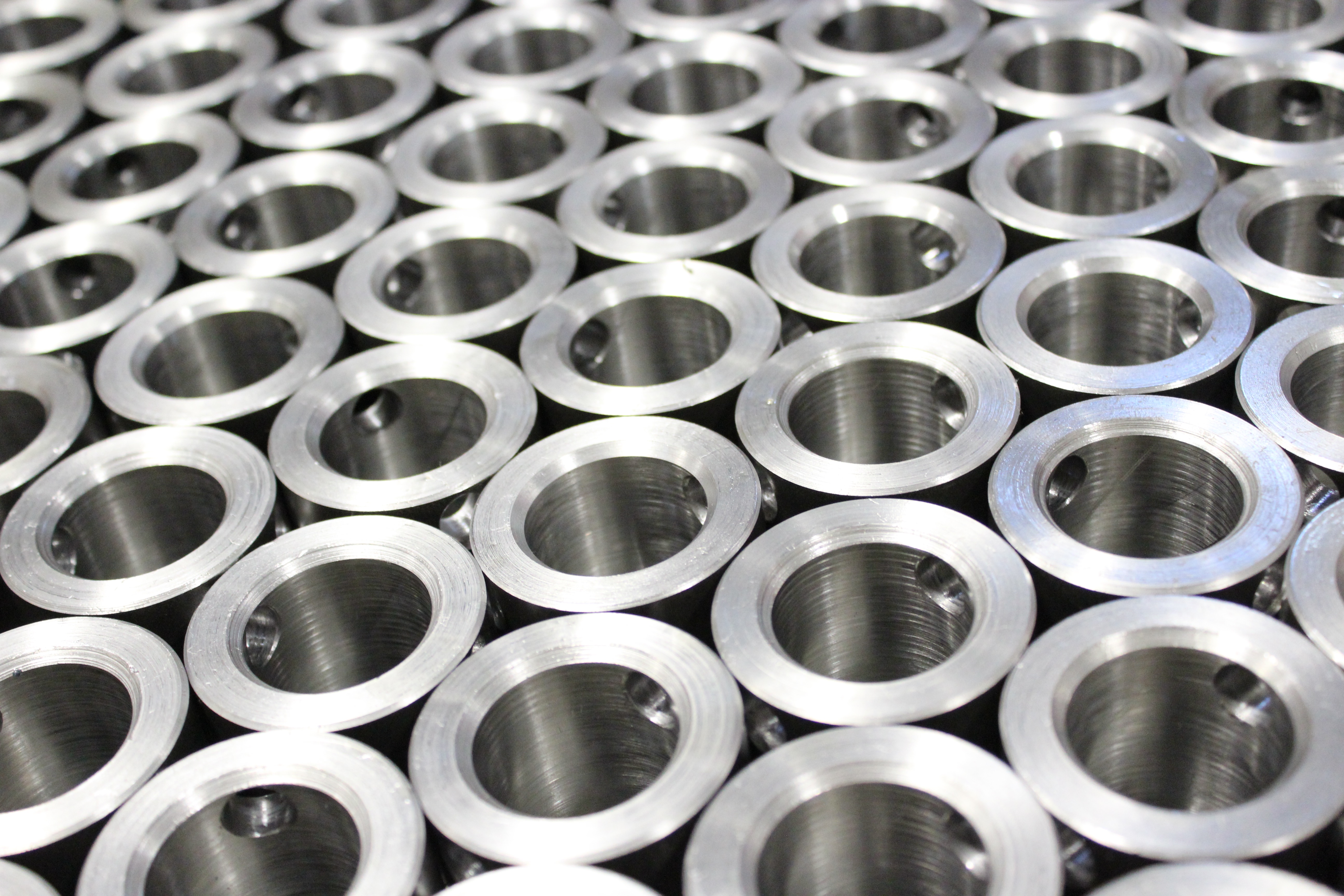

What is High-Volume Production?

The term “high-volume production” can mean many things to many people, from both a supplier and a customer perspective. What does “high-volume production” mean to us here at Cass? We’ve prepared an overview (View PDF) that illustrates the types of parts we run on a daily basis. Our hope is that this overview helps you start thinking about potential matches between your machined-parts requirements and our strengths here at Cass.

Our core-machining competencies include screw machining, CNC milling and turning, Swiss machining and precision grinding. When it comes to high-volume production, our capabilities match up best with parts up to 3.5 inches in diameter and under 12 inches long. Over the years we’ve migrated toward making more cylindrically shaped parts than anything else – at times up to 8 inches in diameter and up to 40 inches in length. The best way to leverage Cass’s machining and grinding capabilities is to release orders to us in the thousands of pieces and up. Through strategic investments in automation, we are running parts with EAUs in the millions without losing a beat.

As you contemplate your next high-volume machined parts supplier, here are five questions you should ask your candidates and why you should ask them:

1. Do you design and manufacture tooling in-house?

In house tooling capabilities will shorten delivery lead times and can aid in quick validation of DFM efforts, advancing you toward more high-volume production releases than your competition.

2. Do you offer JIT programs?

High-volume output needs a place to go. A customized JIT program on high-volume production runs will help you smooth the flow of parts to your assembly floor and provide buffers for those inevitable swings in your production requirements.

3. Do you have the equipment, capabilities and experience to execute high-volume production orders and still maintain the quality and service that we require?

Over time and constant use, tooling, molds and templates wear or can lose detail. A quality assurance team should be well aware of these issues and be able to manage them on high-volume runs via pre-production planning, maintenance, and regularly scheduled quality checks— all part of a solid QMS.

4. What is your on-time delivery performance?

If a machined parts supplier’s on-time delivery performance is not continuously being measured and improved upon, you’ve got a cause for concern.

5. Can you support these four questions with happy customer testimonials?

At Cass we can answer a resounding “yes” to all five of these questions. We continually and strategically invest in automated production and inspection equipment to ensure that even when you need high-volume production, you’ll still get the superior quality you count on from us.

High-volume production orders can be intimidating for some machine shops. Not for Cass Precision Machining. Give us a call at 763-535-0501 or reach us at [email protected] to see if we can help with your high-volume production orders!