Precision grinding is an effective machining process used for finishing and completing metal parts. This technique is most commonly used when a material is too hard to machine efficiently or when the tolerances required are too precise for machining.

Cass Precision Grinding Services

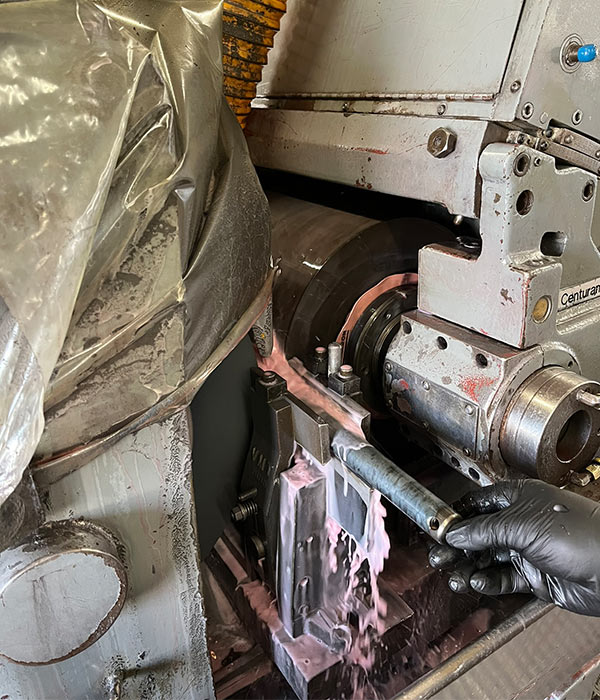

Cass’s comprehensive precision grinding services include cylindrical grinding, centerless grinding, and centerless infeed grinding. We grind a wide variety of materials, including steel, aluminum, brass, bronze, and stainless steel, to your specifications.

Our Precision Grinding Department features over 10 grinding machines, eliminating the need to add another supplier for grinding services while shortening overall delivery lead times. We run Cincinnati, Bryant, Shigiya, Supertec, and Royal Master grinding equipment. We use CNC controls and autoloaders to handle high-quantity orders efficiently.

What is Cylindrical Grinding?

Cylindrical grinding involves the grinding of circular or cylindrical parts between centers to achieve as much roundness of the part as possible. Cylindrical grinding machines coordinate four essential actions: The work part must constantly rotate; The grinding wheel must constantly rotate; The grinding wheel is fed toward and away from the work; Either the part or the grinding wheel is traversed with respect to the other. These machines offer automation to improve efficiency and accuracy.

Cass Cylindrical Grinding Services

We operate multiple cylindrical grinding machines at Cass. We have fully CNC-controlled machines, with others that have two grind axes and feature autoloaders. Our CNC grinders have in-process gauging for continuous monitoring of dimensional compliance as specified. The higher complexity of the grinding requirements on parts like shafts, rollers, bearing journals, cores, mandrels, taper grinds, and more, the better the match with cylindrical grinding equipment.

What is Centerless Grinding?

Centerless grinding achieves roundness, surface finish, and dimensional tolerances among the best available in metalworking. Centerless grinding incorporates the use of two wheels, a regulating wheel and a grinding wheel. It differs from other cylindrical grinding processes in that your parts are not mechanically constrained. Instead, the part is located in the “grinding zone” between the grinding wheel and the regulating wheel on a workpiece support. The rotating grinding wheel and regulating wheel put the part into rotation and remove material. Grinding pressure from the grinding wheel presses the part against the regulating wheel and the workpiece support. The rotating regulating wheel provides the counter-pressure required for grinding.

We can configure standard centerless grinders for high-speed parts loading by slightly tilting the regulating wheel in relation to the grinding wheel and work piece support. The speed and inclination angle of the regulating wheel together determine the part feed rate. This results in a process that is exceptionally efficient as the machine can be loaded during grinding operations. Parts can flow through centerless grinders at speeds well over 1,000 pieces per hour, holding OD grinding costs for parts like pins, spacers, rollers, bushings, and more to a minimum with rapid delivery responsiveness.

Cass Centerless Grinding Services

We operate multiple centerless precision grinding machines at Cass. We’ve configured some machines as standard centerless grinders. The second group of machines are centerless infeed grinding machines that have parts loaded up to a fixed stop to assure precise and consistent part finish results at high speeds. The last machine is configured for thru-feed bar grinding of various brass, bronze, and steel materials.

Have Questions or Want a Quote?

Our precision grinding experts are happy to help!

Our Core Values

CARE ABOUT

OTHERS

GO THE

EXTRA MILE

COLLABORATE

TOGETHER

SOLVE

PROBLEMS

EXPECT

EXCELLENCE