Cass Customer Success Stories

At Cass, your satisfaction is our top priority. These are some of our customer success stories!

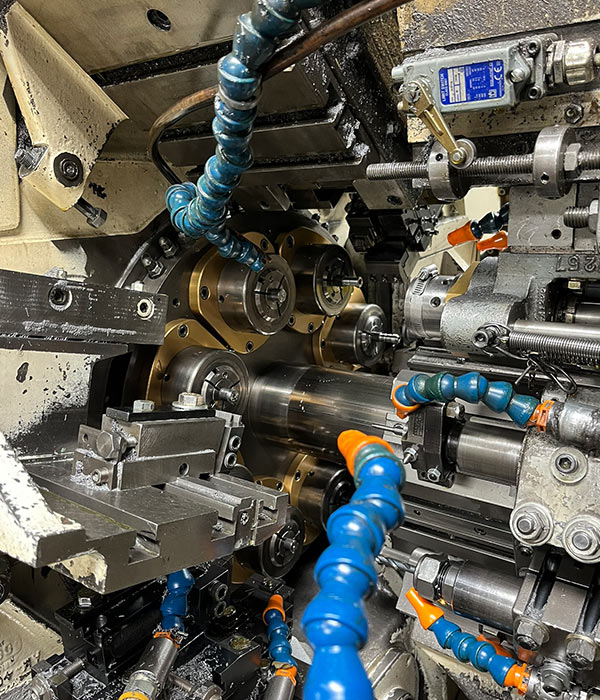

Cooling Couplings

PROJECT OVERVIEW: A company had a valuable business opportunity to supply cooling couplings in the growing data center market. The total available market to the company was extremely large, so they wanted to find a reliable machining partner immediately.

CHALLENGE: The company needed to find an outsourced partner that could scale volume quickly and meet an aggressive price point, which can be difficult in the manufacturing realm.

SOLUTION: With a steadfast commitment to operational agility, Cass quickly understood the technical and financial requirements and developed a turnkey solution for the customer. The solution required significant investment in new equipment by Cass that was operational in record time. Cass continually invests in our technology to offer our customers the most optimal solutions at competitive pricing.

Pilot Pin

PROJECT OVERVIEW: A company contacted Cass for a quote on a pilot pin that was a critical, perishable fixturing component in their process.

CHALLENGE: This company had been consistently having delivery and finish quality issues with multiple vendors and needed to find a reliable machining partner with on-time deliveries and high-quality standards.

SOLUTION: With a comprehensive quality assurance system in place to guarantee finished part specifications, as well as the ability to ship on time every time, Cass was the ideal partner. We reviewed the current drawing and compared it to the customer-supplied component samples. When analyzed, the samples had a much higher level of finish than depicted in the drawing. Our experienced engineers updated the drawing to represent the samples, added additional machining and finishing processes, and produced perfect parts in record time.

Screen Plungers

PROJECT OVERVIEW: A company contacted Cass about a group of new screen plungers they were looking to have prototyped. After analyzing their options, they would decide which prototype would be going into production.

CHALLENGE: The company required prototypes to decide on the plunger’s design before supplying them to their screen assembly contractors prior to the next season’s product rollout.

SOLUTION: As an experienced machining partner that specializes in rapid prototyping and streamlined production, Cass was up for the challenge. We quickly produced a group of prototype plungers and worked with the customer on the Design for Manufacturing (DFM) adjustments. After R&D and prototyping, Cass was able to ramp up to full production and supply the customer with their new screen plungers on time.

Pin Cell

PROJECT OVERVIEW: A company required a custom pin cell solution for lights-out machining.

CHALLENGE: This company required a high-profile pin with more consistent throughput and dedicated equipment, which was no easy task for many machining companies.

SOLUTION: As no strangers to fulfilling custom requests, Cass created a custom lathe cell that maximized throughput while having minimum attendance from a machinist. This was accomplished by creating custom extractors that pulled completed parts out the back of the sub-spindle to a gravity rail. In addition to having a custom bar loader, the machine can run for nearly an entire shift, streamlining operations for the customer to promote future success.

Pin Cell #2

PROJECT OVERVIEW: A company came to Cass with a revision change to a pin.

CHALLENGE: The company’s current vendor was not meeting the supply, and the company was looking to move the whole part from them.

SOLUTION: Leveraging operational agility to meet this request, Cass had to determine how to best use the capacity we had to meet the aggressive, under-lead-time schedule. There was also the added challenge of finding enough raw materials to meet the demand. Cass used a combination of the pin cells they had developed for making pins, as well as the method used to manufacture pins before the pin cells. By doubling up production methods, we met the customer’s delivery goal. We worked through the lack of raw materials by using larger materials and grinding them down to the desired size. With some resourcefulness and ingenuity on our part, simple fixes were all it took to meet the customer’s needs.

Corrosion Issues

PROJECT OVERVIEW: A company’s customer was having corrosion issues in the field.

CHALLENGE: This company needed to find out why they were having corrosion issues before implementing a plan to correct the design/issue.

SOLUTION: Cass worked diligently with an expansive group of engineers in a joint effort for over 10 months. We discovered that the corrosion was coming from a breakthrough during the finish grind of the plating. After more investigation, we found that the plating was not going on evenly, thus allowing for the breakthrough. We also conducted other investigations by looking at rod placement on the plating rack and thicker plating deposits. Ultimately, we worked with the customer and vendor to develop a method of testing to see if there was a breakthrough to keep damaged parts out of the field. With collaboration, diligence, and hard work, we were able to determine a solution moving forward.

Cobot Mill Cell

PROJECT OVERVIEW: A company required an automated Cobot mill cell.

CHALLENGE: The company required an automated Cobot mill cell due to increased production demands. However, Cass still had the same amount of labor to run the Milling Department, so we had to determine the best solution to meet the customer’s needs.

SOLUTION: Leveraging our operational agility and dedicated employees, our expert engineering team implemented a Cobot with end-arm tooling that loaded blanks into the mill. This improved throughput and quality control for the process, which ultimately drove cost out of the part.

We'd love for you to join our CUSTOMER SUCCESS STORIES.

Connect with our machining experts to get a conversation started!

Our Core Values

CARE ABOUT

OTHERS

GO THE

EXTRA MILE

COLLABORATE

TOGETHER

SOLVE

PROBLEMS

EXPECT

EXCELLENCE